NABL certified Quality control initiatives

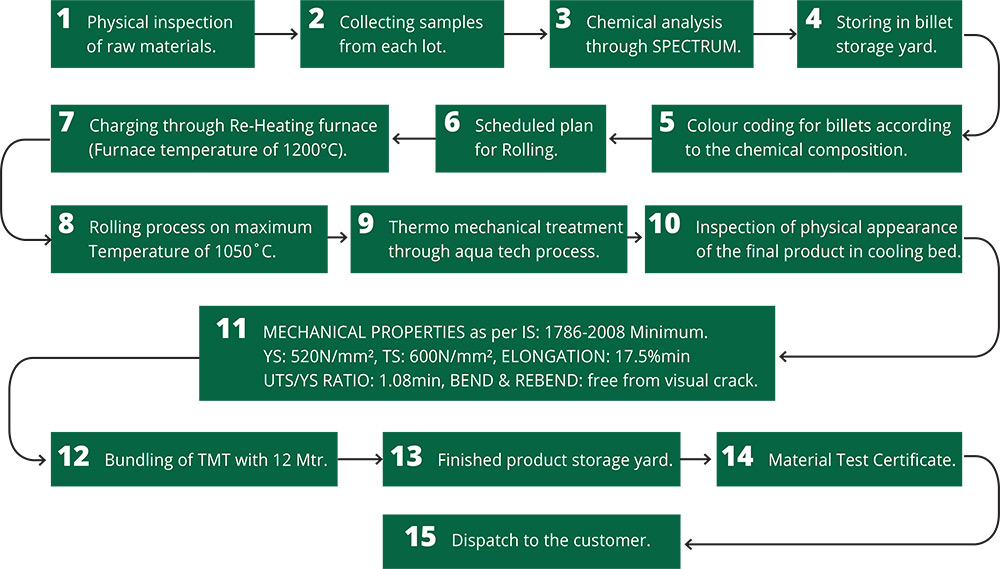

Bharathi is one of the very few TMT brands in South India with a quality checking laboratory accredited by NABL. Facility for online quality checking too is in place. In every stage of the manufacturing process, Bharathi TMT bars are rigorously tested for quality in this NABL accredited laboratory. Various factors such as the carbon content in billet samples, sulphur, manganese, nitrogen and so on are tested using BRUKER Q4 TASMAN 130, which is a high-end German-made optical emission spectrometer to ensure that they meet the BIS standards. Factors such as Yield stress, Tensile stress, Elongation, Bendability and Re-bendability of the manufactured TMT bars are tested in the laboratory at exact intervals. Apart from this, the quality control division promptly tests the proper addition and section weight of Fe 550D grade chemical objects mandated by BIS. The 550 D grade TMT bars from Bharathi are thus thoroughly tested for quality, ensuring unmatched strength and added ductility. Bharathi TMT steel bars come to the market only after attaining Test Certificates f or advanced quality. Customers can understand all about the details of these test certificates by scanning the QR code in the product tags that come with our Bharathi TMT steel bars.